PRODUCT DETAILS

1. Introduction to the integrated water, fertilizer and medicine machine

According to the equipment type, it can be divided into fixed type and parallel mobile type.

During fertilization, the sprinkler is always in a moving state, and the working performance requirements of the fertilization device are relatively high. It is necessary to ensure that the flow rate or concentration of the fertilizer liquid injected into the sprinkler remains unchanged and is not affected by the water pressure changes in the main water pipeline of the sprinkler. Therefore, the differential pressure fertilizer tank and Venturi fertilizer applicator widely used in drip irrigation system and micro sprinkler system are not suitable for fertilization of large sprinklers.

The pump-injection fertilization device specially matched with large sprinklers consists of a fertilizer storage tank, a stirrer, a pump flow rate constant tube, a fertilizer injection pump, an injection nozzle, an anti-siphon backflow device and connecting accessories. The fertilization device relies on an electric-driven fertilizer injection pump to provide power, extract the evenly stirred fertilizer liquid in the fertilizer storage tank, and inject the fertilizer liquid evenly into the water pipe of the sprinkler through the injection nozzle. After mixing and diluting with irrigation water, it is sprayed by a suspended low-pressure nozzle to realize the integrated operation of water and fertilizer.

The center point of the pointer sprinkler is fixed, so the fertilization device can be placed not far from the center point of the equipment.

The fertilization device of the translation sprinkler is installed on the center car and moves with the movement of the sprinkler.

2. Composition of water and fertilizer integration

1. Special plunger pump

Maximum working pressure: 1.0Mpa

Working temperature: 0-40℃

Flow range of plunger pump: 150L/300L/450L/600L

Flow adjustment range: 10%-100%

Liquid viscosity: 0.3-1000cps

The fertilizer injection pump that meets the working requirements of the fertilization device should be a positive displacement pump. Generally, plunger, piston, and diaphragm fertilizer injection pumps can be selected. It should be noted that the selection of the fertilizer injection pump should take into account the irrigation area of the sprinkler, the flow rate and pressure of the sprinkler, and the purpose of the calculation is to ensure the concentration of the fertilizer solution.

2. Fertilizer storage barrel

The fertilizer storage barrel is designed to be a round cylinder or square shape. The bottom of the barrel should be designed to be a conical structure and supported by a bracket, which can easily drain the fertilizer liquid and clean the fertilizer storage barrel. The top of the barrel is equipped with a fertilizer inlet with a diameter of 40-50cm and a clean water inlet with a diameter of 5cm. For easy operation, the top of the barrel should not be more than 1.5m from the ground. The volume design of the fertilizer storage barrel also needs to consider the irrigation area of the sprinkler and the flow rate into the machine, and it should not be too small. At the same time, the processing and transportation costs and ease of use of the fertilizer storage barrel are also required. Generally, there are different specifications such as 1000L, 1500L, 2000L, 3000L, etc.

3. Agitator

The electric agitator can improve the dissolution effect of soluble fertilizers, make the fertilizer liquid fully mixed, and make the conductivity EC value and pH value more accurate and stable. The agitator needs to consider the volume of the fertilizer storage tank.

4. Anti-backflow fertilizer injector

Maximum working pressure: 1.0Mpa

Working temperature: 0-40℃

Flow range of plunger pump: 150L/300L/450L/600L

Anti-siphon, anti-backflow

¾” or 1” threaded interface

It is the key equipment of pump-injection fertilization device, and its performance plays an important role in the uniformity of irrigation and fertilization and the good operation of the system. When designing the injection nozzle, in addition to requiring it to have good hydraulic and mechanical properties, simple structure and reliable operation, it must also have the following two functions: good mixing effect of spraying fertilizer liquid and irrigation water; one-way check function to prevent irrigation water from flowing back.

5. Pump flow rate tube

During sprinkler irrigation and fertilization, the flow rate of the fertilizer pump can be changed according to the actual situation, and the actual flow rate of the fertilizer pump needs to be accurately measured. The pump flow rate tube and the fertilizer storage tank form a connecting vessel and work together, and the outer wall of the tube is attached with a scale. During the measurement, by observing the change in the height of the fertilizer liquid in the rate tube of the fertilizer pump within a certain working time, the change in the volume of the fertilizer liquid in the fertilizer storage tank is calculated, and the actual flow rate of the fertilizer pump is calculated. The rate tube has a simple structure, easy operation, and high measurement accuracy. You can also analyze the concentration of the fertilizer solution by collecting the EC value and pH value of the solution in the fertilization pipeline in real time.

6. Other devices

To prevent fertilizer liquid from flowing back, check valves need to be installed on the sprinkler water supply pipe and the fertilization system pipe. The suction port of the fertilization system should be equipped with an anti-backflow device; at the same time, a filter device must be installed downstream of the test fertilizer solubility to remove undissolved fertilizers or other impurities.

III. Water and fertilizer integrated installation

1. The control panel of the water, fertilizer and medicine integrated machine system is usually integrated into the control cabinet of the sprinkler equipment. It only needs to provide the equipment linkage function (that is, the fertilization system will only have electricity when the equipment is operating normally) and provide three-phase electricity (it should be noted that some foreign regions use different voltage standards and the voltage level and voltage level must be specified before ordering).

4. When the sprinkler is integrated with water and fertilizer, it is necessary to coordinate the matching relationship between fertilizer characteristics, unit operating parameters and fertilizer pump characteristics. Various parameters need to be accurately calculated, mainly considering the following factors:

1. Fertilizer amount

2. Stock solution concentration

3. Total volume of stock solution

4. Spray fertilizer solution concentration

5. Unit travel speed

6. Fertilizer injection time

7. Spraying water fertilizer/clear water depth

V. Requirements for fertilizers in water-fertilizer integration.

1. Highly soluble fertilizers should be selected, which can be completely and quickly dissolved in irrigation water at field temperature, will not block filters and nozzles, and have low insoluble content;

2. At the same time, the fertilizers should be highly compatible, and there should be no antagonism between the configured fertilizers, and there is basically no precipitation;

3. Low corrosiveness: low corrosiveness to control equipment and irrigation systems.

FACTORY APPEARANCE

Our products have passed ISO, CE and other international authoritative certifications, and our products meet the standards of mainstream markets in Europe, America, the Middle East and other markets, ensuring unimpeded export trade and enhancing customers' confidence in cooperation. We provide modular and customized irrigation system designs for different terrains, crop types and planting scales to meet the needs of diverse agricultural scenarios around the world.

PACKING AND SHIPPING

Provide installation and commissioning, technical training and remote operation and maintenance services, 24-hour response to customer needs, to help overseas customers quickly get started and solve the use of difficult problems.

CERTIFICATES

Through the ISO, CE and other international authoritative certification, the product meets the international market standards

YIHE EXHIBITION

FAQ

Q: How about the after-sales service?

Q: How about installation?

Q: Can you give me some equipment samples?

Q: Are you a factory or a trading company?

Q: Do you have a minimum order quantity?

Q: How to order online?

Integration of water and fertilizer

Key words:

Integration of water and fertilizer

Classification:

Water and fertilizer integration

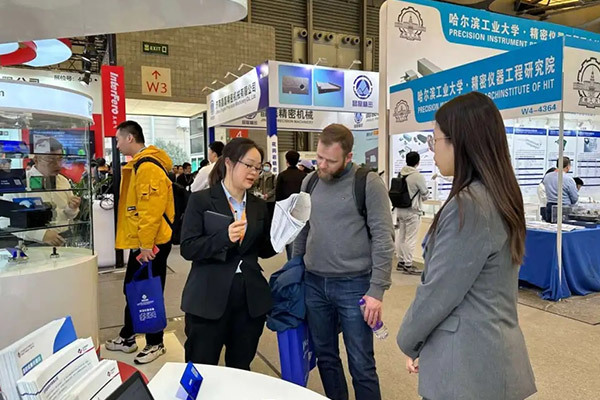

CUSTOMER VISIT

Free access to consultation information

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

RECOMMEND PRODUCTS

We have a R&D team and production line to provide quality assurance for the products leaving the factory. We sincerely look forward to in-depth cooperation with you!

Center Pivot Irrigation Machine

Water and fertilizer integration

Center Pivot Irrigation Machine

New customers enjoy 10% product discount

PRODUCT CENTER

CONTACT US

Address: 2-1-2301, Phoenix International Plaza, High-tech Zone, Jinan City, Shandong Province

Quality of service to win customer satisfaction

Shandong Yihe Agricultural Technology Co., Ltd.